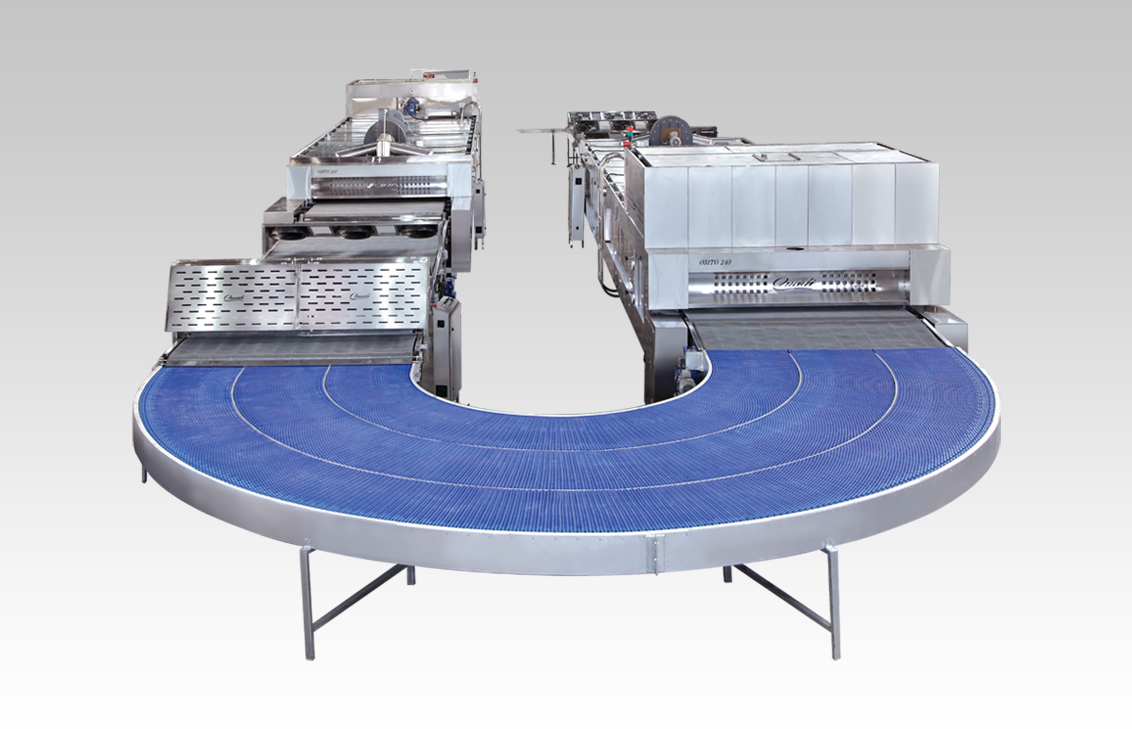

Dry cookie depositor is a machine used for extruding formable type of dough which is possible to produce products from 10 – 50g; the maximum diameter extrudable is from 20 mm to 60 mm.

The machine is just an extruder for extruding and cutting the product to the desired thickness and length.

After the products are extruded, they are transferred to the tunnel oven for baking.

The tunnel oven is manufactured in different width from 100 cm to 250 cm, which is good enough for mass production.

The products are then cooled on the cooling conveyor equipped with cutting systems. An optional ultrasonic cutter system is available on request for cutting the products with a minimum thickness at high speed. (0.8-2 cm thickness) After cutting, the products are transferred to the stacker, and then they pass through the second baking unit of the tunnel oven with a wire mesh belt. After baking, products are transferred to the second cooling system, the cooling conveyor, and finally the handling and packing section.

The line has been designed for the utmost variety of capabilities & capacity. For this purpose, lots of additional accessories are insertable within the layout. Each line is designed according to the final product machinery & equipment considering available space.

The line mainly consists of:

Used for: Extruding formable types of dough which is possible to produce products from 10 - 50gr

The same system could be used with slight changes for “Dry Cakes or RuskCakes”.To produce Rusk cakes, primarily the ingredients are first mixed, transferred to the hemogenizer for aeration, pumped through pipes to the depositor, deposited into rectangular moulds, & then transferred automatically to the tunnel oven for baking. There is an auto discharge of the rectangular cakes to the conveyor, where after the cakes are cooled on the spiral cooler or the cooling conveyors, they are sliced to the desired thickness. Sliced cakes are then transferred to the secondary baking, & accordingly, to secondary cooling. Finally, they are transferred to the handling & packing.

The line has been designed for the utmost variety of capabilities & capacity. For this purpose, lots of additional accessories are insertable within the layout. Each line is designed according to the final product machinery & equipment considering available space.

The line mainly consists of:

Used for: Producing Rusk Cakes

|

Production Capacity

|

Product Weight

|

Required Space

|

Power Consumption

|

Gas Consumption

|

|---|---|---|---|---|

|

300-500 kg/h

|

10- 50 g

|

36 x 12 m2

|

60 kW

|

40 - 50 m3

|

|

400 - 700 kg/h

|

10 - 50g

|

54 x 12 m2

|

80 kW

|

80 - 100 m3

|

|

700 - 1000 kg/h

|

10 - 50 g

|

74 x 12 m2

|

100 kW

|

130 - 150 m3

|

Download Catalog

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy