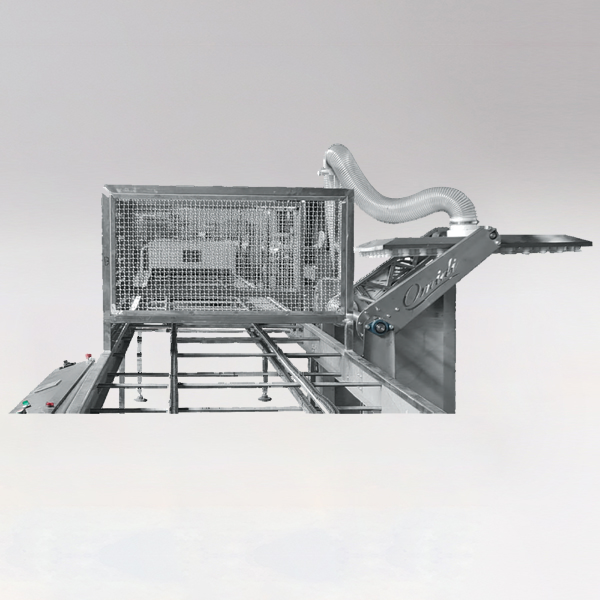

An integrated line designed to create your target product to match and fulfill the market demands for cupcakes and muffins.

The line has been designed for the utmost variety of capabilities & capacity. For this purpose, lots of additional accessories are insertable within the layout. Each line is designed according to the final product machinery & equipment considering available space.

The line mainly consists of:

The additional accessories include:

Used for: Mixing Cupcake Dough/Mainly for Liquid & Primary Mixing

Used for: Depositing dough into tray molds with single or double color

Used for: Automatic Feeding Without Hand Interference

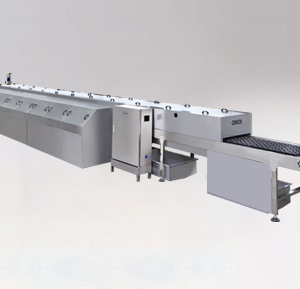

Used for: Baking Cup cakes.

Used for: Transferring the Products Tray From Tunnel Oven

Used for: Lifting the Baked Cupcakes Without Hand Intervention

Used for: Injecting Chocolate & Marmalade

Used for: Cup Cake Automation System to Wash up the Trays.

Used for: Transporting Trays to the Depositor

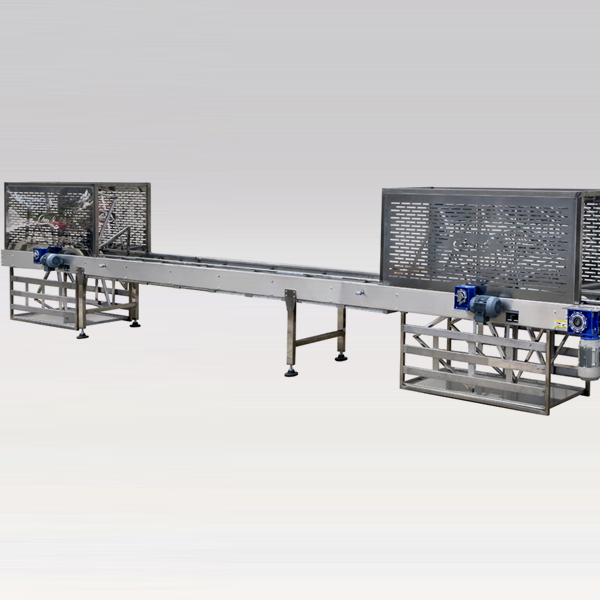

Used for: Transferring the products to spiral

Used for: Cooling the Products

Used for: Returning Trays

Used for: Transferring the products to packing

Used for: Packing the finished product

|

Production Capacity

|

Product Weight

|

Required Space

|

Power Consumption

|

Gas Consumption

|

|---|---|---|---|---|

|

400-700 kg/h

|

15- 150 g

|

41 x 15 m2

|

60 kW

|

40 - 50 m3

|

|

700 - 1000 kg/h

|

15 - 150g

|

53 x 15 m2

|

73 kW

|

50 - 75 m3

|

|

800 - 1300 kg/h

|

15 - 150 g

|

70 x 15 m2

|

90 kW

|

75 - 100 m3

|

Download Catalog

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy