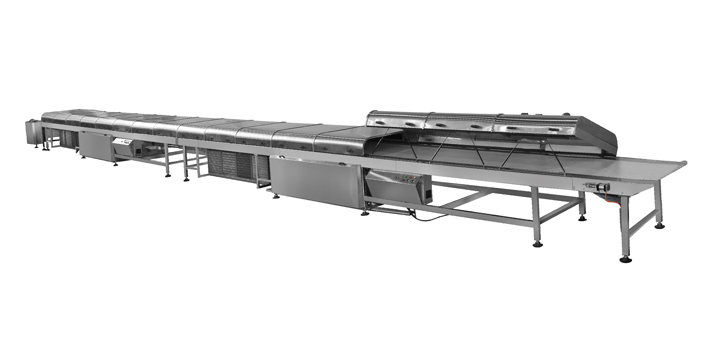

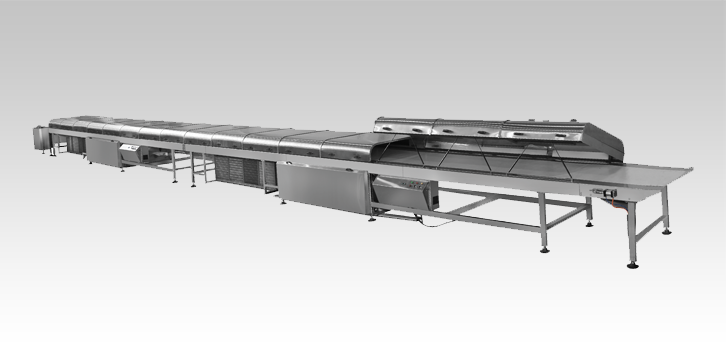

Chocolate enrobing lines includes enrobing machine and used for different applications, manufactured in different standard width, and cooling tunnels

designed with high accuracy and maximum insulations according to different required cooling times Chocolate enrobing the products with high accuracy, minimum chocolate, and full coverage. The machine is designed to obtain a standard temperature for suitable coating of chocolate in the machine tank and fulfill perfect coverage of products with the minimum quantity of chocolate

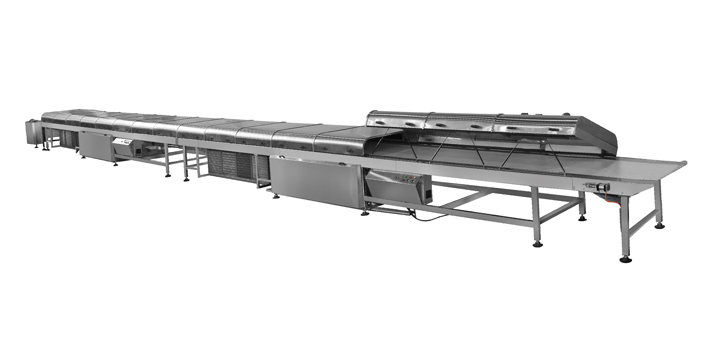

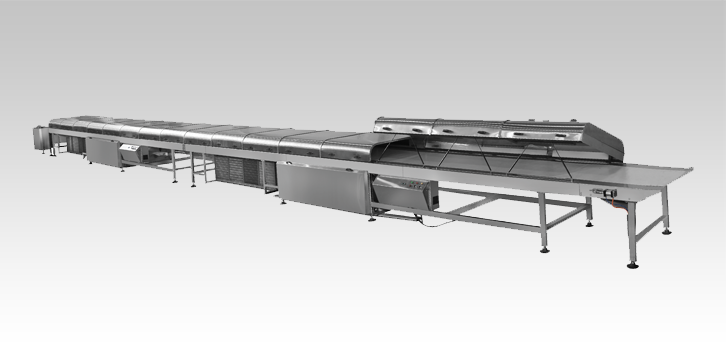

Chocolate enrobing lines includes enrobing machine and used for different applications, manufactured in different standard width, and cooling tunnels

designed with high accuracy and maximum insulations according to different required cooling times Chocolate enrobing the products with high accuracy, minimum chocolate, and full coverage. The machine is designed to obtain a standard temperature for suitable coating of chocolate in the machine tank and fulfill perfect coverage of products with the minimum quantity of chocolate

Cooling tunnel : Used for cooling the products after enrobing or used as a refrigeration system for cooling the products . Equipped with compressor, condenser & evaporator. Stainless steel structure, with perfect insulation for obtaining the ideal temperature. Capable of obtaining up to -10°C for refrigeration & cooling the products based on application. The cooling tunnel doors are designed into the standard length make it easy to open & close which enables easy cleaning & high efficiency.

Cooling tunnel : Used for cooling the products after enrobing or used as a refrigeration system for cooling the products . Equipped with compressor, condenser & evaporator. Stainless steel structure, with perfect insulation for obtaining the ideal temperature. Capable of obtaining up to -10°C for refrigeration & cooling the products based on application. The cooling tunnel doors are designed into the standard length make it easy to open & close which enables easy cleaning & high efficiency.

Used for: Preparing fine chocolate which is used for the filling or the chocolate enrobing machine for coating the products

Used for: A suitable machine for producing extruded & co-extruded products, equipped with 2 hoppers

Used for: Producing nutrition bars using nuts, dried fruit, sesame and granules, etc mixed with glucose and syrup

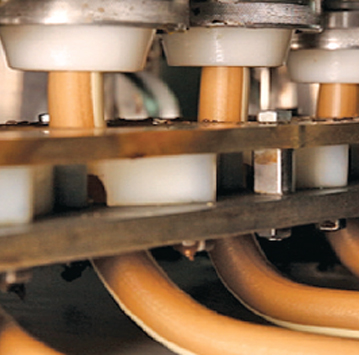

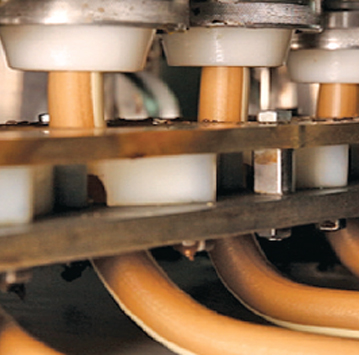

Used for: The enrober machine can coat a wide range of products completely with the minimum auantity of chocolate

The enrober machine can coat a wide range of products completely with the minimum auantity of chocolate

The enrober machine can coat a wide range of products completely with the minimum auantity of chocolate

Used for: The enrober machine can coat a wide range of products completely with the minimum auantity of chocolate

|

Production Capacity

|

Product Weight

|

Required Space

|

Power Consumption

|

|---|---|---|---|

|

25000 - 32000 pcs/h

|

10 - 100g

|

45 x 8 m2

|

60 kW

|

Download Catalog

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy