Sponge Cake line is designed to shape a wide range of sponge cakes.

The line has been designed to operate a heavy-duty line 24/7, where placing lots of option within the line, enables a wide range of new shapes and types of producible products.

The line consists of 3 major sections.

A very important part of the production procedure is where ingredients are added & turned into a smooth dough in the premier& then transferred to a homogenizer by the pump for aeration, which helps a smooth, spongy and light texture cake.

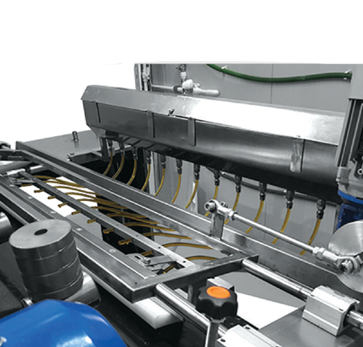

The sponge cake mix just after aeration is transferred to the depositor which consists of a hopper where the main mission is to deposit a homogeneous dough within the sheet onto the tunnel oven belt with desired thickness before the tunnel oven.

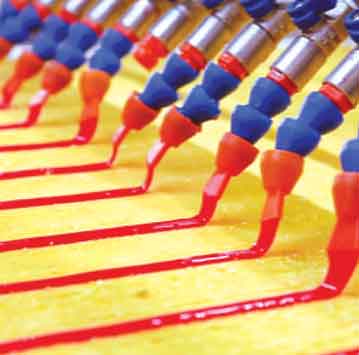

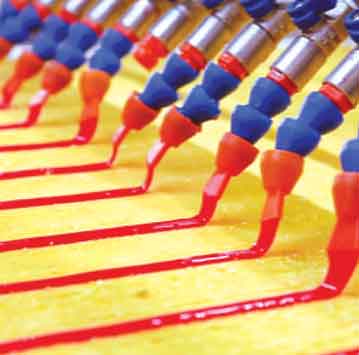

There is a decorating option that can design zigzag lines with a different color of dough and is equipped with a tank for decorating mix. (Further option, includes granule and powder sprinkling device.) which are attachable to the line for more variety of products.

Designed with an ideal entrance length for placing creative options to develop a lot of product variety at the inlet of the tunnel oven equipped with a belt lubrication system.

The tunnel oven is designed to bake a perfect sponge cake sheet with cyclothermic system indirect heating, where the hot air is circulated through the pipes designed on top and bottom of the tunnel oven belt. The temperature of the upper and lower pipes are individually adjustable; in addition, Dampers have been designed for each pipe to enable further heat control.

Used for: Mixing Primary Ingredients

Used for: Aeration the Dough

Used for: Combine Mixing Process

A suitable baking system designed for accurate baking of Sponge/Layer Cake sheets

Used for: Decorate the dough with zigzag movement

Used for: Direct the cake sheet dough on the tunnel oven belt

Used for: Spread oil on the belt accurately in the form of drops

Used for: Save space and return the line

The enrober machine can coat a wide range of products completely with the minimum auantity of chocolate and coolung tunnel is designed to cool the desired products

|

Production Capacity

|

Product Weight

|

Required Space

|

Power Consumption

|

Gas Consumption

|

|---|---|---|---|---|

|

400 - 700 kg/h

|

15 - 300g

|

52 x 15 m2

|

63 kW

|

30 - 40 m3

|

|

700 - 1000 kg/h

|

15 - 300g kg/h

|

66 x 15 m2

|

78 kW

|

45 - 60 m3

|

|

1000 - 1600 m3

|

15 - 300g

|

80 x 15 m2

|

100 kW

|

60 - 80 m3

|

Download Catalog

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy