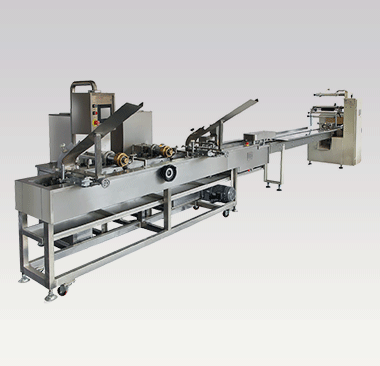

These lines are designed for soft and hard biscuit.Consist of many components and devices, in which each of the machinery is manufactured to fullfill the utmost quality for each biscuit type:

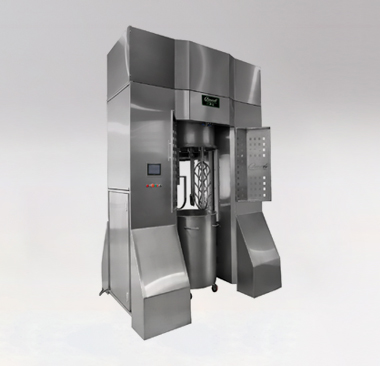

Used for: Mixing Biscuit Ingredients

Used for: Mixing hard & soft dough

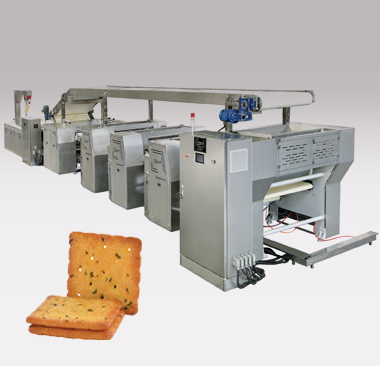

Used for: Soft Biscuit

Used for: Snack Biscuits

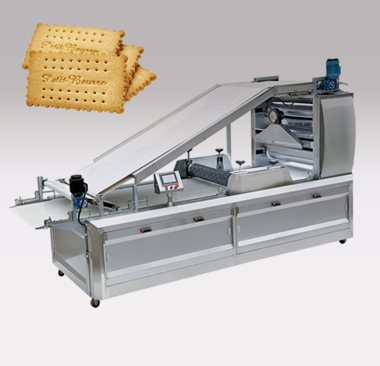

Used for Petit Beurre Types

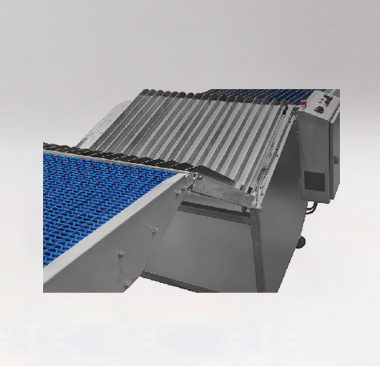

For: Cooling & Transferring

Used for: Baking Products

UsedFor: Aligning Biscuits Before Packing

For: Cooling Stacked Biscuit

For: Applying Single or Double Flavored Cream & Packing Biscuit

|

Machine

|

Production Capacity

|

Required Space

|

Power Consumption

|

Gas Consumption

|

|---|---|---|---|---|

|

Soft Biscuit

|

400-1000 kg/h

|

73 x 12 m2

|

72 kW

|

45 - 60 m3

|

|

Hard Biscuits

|

400 -800 kg/h

|

85 x 12 m2

|

64 kW

|

45 - 60 m3

|

Download Catalog

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy

Contact Us

© 2023 Omidi Industrial Machinery.

Privacy Policy